Details

Assembled Roving For Filament Winding

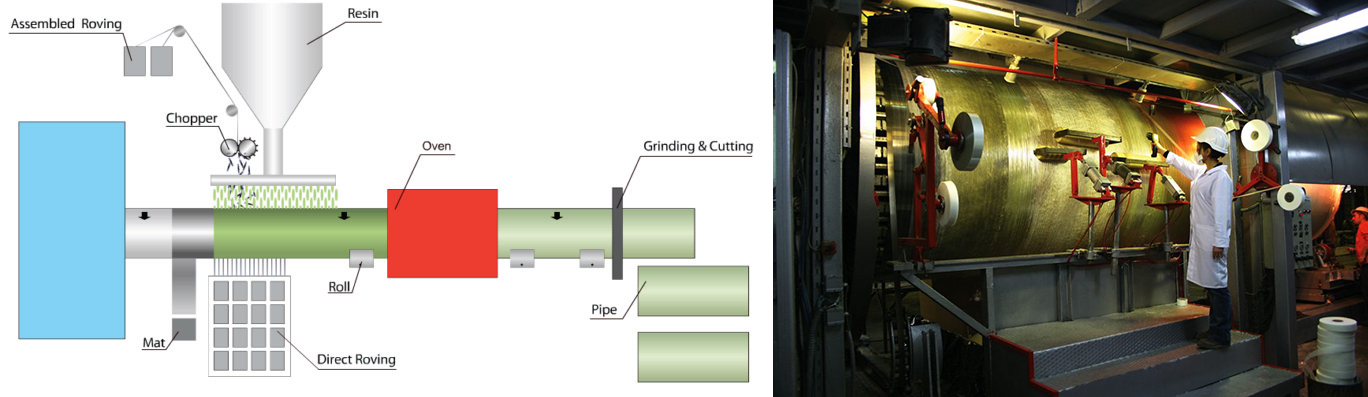

Assembled Roving for Filament Winding is specially designed for FRP filament winding process and compatible with UP, EP and VE resins. Its final composite product delivers excellent mechanical properties. It is designed for continuous filament wound pipes.

Product Feature

● Excellent choppability and dispersion● Excellent use process performance and low fuzz

● Excellent chemical corrosion resistance and aging resistance

● Rapid and complete wet-out and good bonding with resins

Specification

Glass Type

ECR

Sizing Type

Silane

Linear Density (Tex)

2400

4800

9600

Filament Diameter (μm)

13

14

16

Technical Paramenters

|

Linear density variatio(%) |

Moisture content(%) |

Loss on ignition(%) |

Tensile strength(N/tex) |

|

ISO1889

|

ISO3344

|

ISO1887

|

ISO3341

|

|

±6 |

≤0.10 |

0.55±0.15 |

150±20 |

Applications

Continuous filament winding process

Packing Method

|

Average Coil Weigt—21.5Kg Inner coil diameter—160 mm Outer coil diameter—310 mm Bay height - 260 mm |

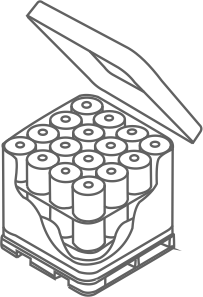

|

Number of coils in a layer — 12 Number of layers — 3 or 4 Net weight of the pallet is about 770 kg or 1040 kg Pallet dimensions — 112 x 112 x 92 cm or 112 x 112 x 118 cm (L x W x H) |

|

Storage

The fiberglass products should be stored away from heat and moisture, and in their original packaging. The best conditions are: temperatures between -10 ºC and 35 ºC; humidity between 35 and 65 %. If the product is not stored under these specifications, it is advisable to condition it in the workshop for at least 24 hours before use, to prevent condensation.

To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.